Products

High Efficiency Water Reducing Agent

Operative Norm

GB8076-2008, Concrete Adxtures; GB8077-2012, Test Method for Concrete Adxtures; GB50119-2013, Technical Specification for the Application of Concrete Adxtures.

Mechanism Of Action

This product is an efficient water reducer with steamed sodium sulfonate formaldehyde hypercondensed polymer as the main component.The water tant is a surfactant.Also known as plasticizer, dissolved in liquid.It is also arranged as oriented on the liquid surface.This reduces the interface energy.This phenomenon is called suractivity.A substance with this surfacactivity is called a surfactant.The surfactant molecule is composed of two parts.Part is an oleophilic group soluble and insoluble in water.As an abhorrent base. The other part is a hydrophilic base that is easy to water and not soluble in oil.When the hydrophilic nature of the hydrophilic group is greater than the hydrophilic group.Such surfactants are considered hydrophilic.Otherwise, it is water-repellent.

After the product is dissociated in water, it is adsorbed to the surface of the cement particles in its base orientation arrangement. Electrostatic electricity is generated.Due to the isoelectric phase repulsion action.Disthe cement particles.Release the free water wrapped in the original polycoagulation form.To achieve the purpose of water reduction.

Performance Indicators

1. This product has a good water reduction rate, has a good water reduction performance under the low mixing amount, especially in the high grade concrete (above C50) effect, its water reduction rate can reach 38%.

2. This product has good early strength and enhancement effect, and the early strength and enhancement effect of concrete mixed into this product is higher than other types of water reducer.

3. The product has the appropriate gas content, and can be adjusted according to the actual needs of the project.

4. This product does not contain chloride ion, sodium sulfate, with low alkali content, no corrosion to steel bars, so it can greatly improve the concrete durability.

5. This product has size stability, the concrete mixed into the product can effectively improve its shrinkage and distortion performance, and reduce the crack risk.

6. This product has excellent water protection performance, no water extraction, no separation analysis, easier to achieve construction operation.

7. This product does not contain formaldehyde, no ammonia release amount, is an environmentally friendly water reducer

Technical Indicators

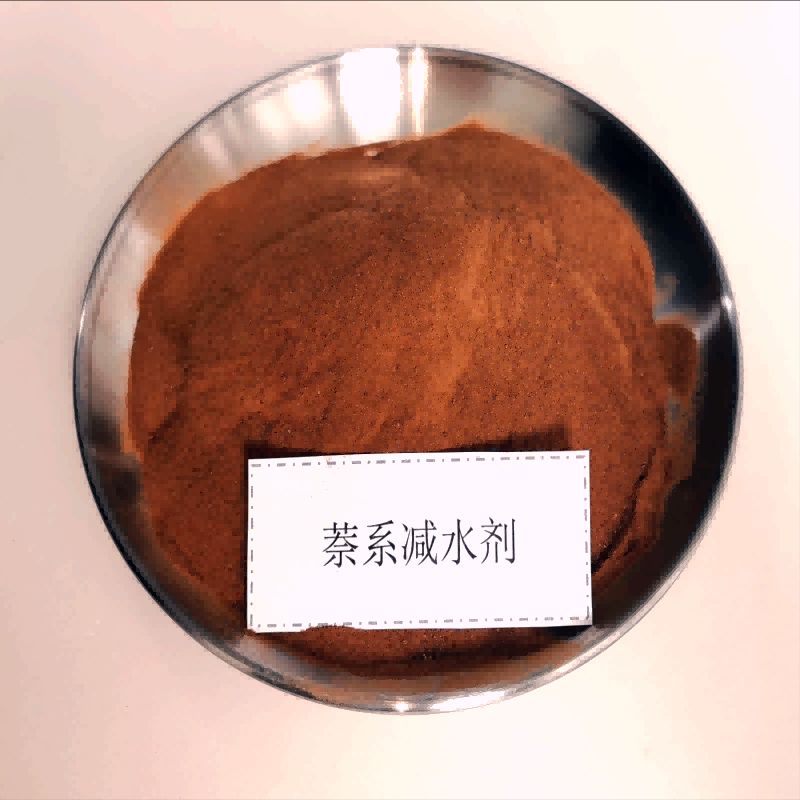

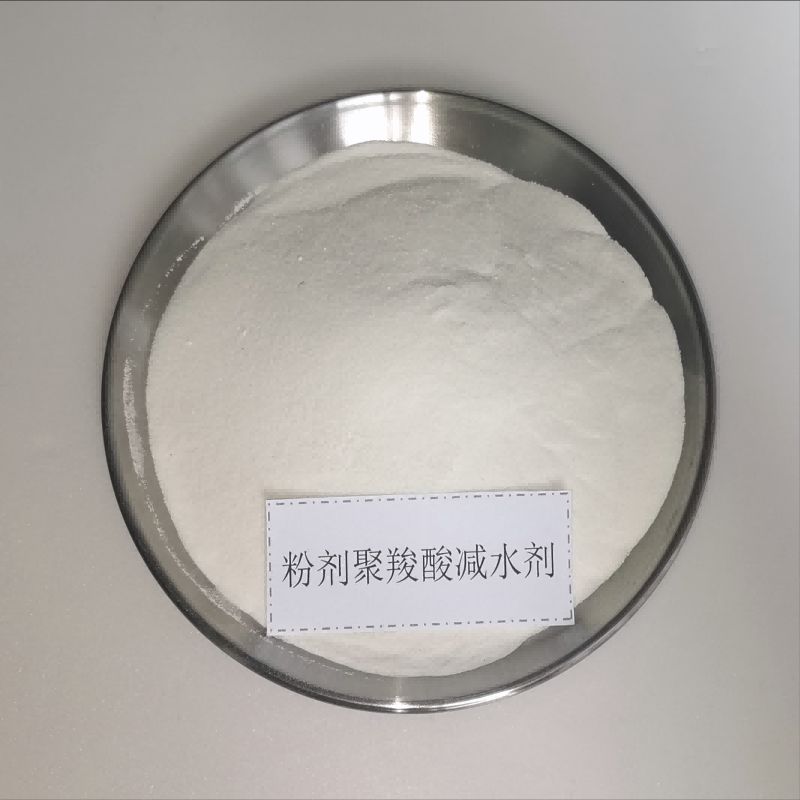

l. The product is divided into powder and liquid.The powder is brownish-yellow.The liquid is brownish-brown.The product is non-toxic, odorless and non-combustible.There is no corrosion effect on the steel bars.

2. This product has an obvious water reduction and dispersion effect.Water reduction rate is between 14 and 25% (adjusted according to user requirements and cement adaptability).There is a wide range of adaptability to cement.

3. Add the product to the wet condensate, under the same cement dosage and the same slump conditions, its 1d compressive strength can be improved by 40% to 110%, 3d compressive strength by 40%~90%, 7d Hangzhou compression strength can be improved by 30~80%, and 25% to 50% to greatly improve the physical and mechanical performance of 50% of concrete.Make the compression and folding strength of the concrete.The elastic modulus and durability are improved accordingly.

4. Improve the ease of concrete mixing mixture and increase the slump.In the same cement dosage and water to ash ratio.Join this product.The slump of the concrete can be significantly increased.Improve the ease of concrete. The slump can increase by more than 12cm.

5. Maintain the same slump and strength level.Join this product.Can save more than 12%.

6. The condensation time and freezing-thaw level can be adjusted according to the actual needs of the project.

|

project |

index of standard |

|

|

Sodium sulfate content was%≤ |

20 |

|

|

PH price |

8~9 |

|

|

Finity% (0.315mm sieve surplus) |

15 |

|

|

Water reduction rate%≥ |

14 |

|

|

Water output rate ratio to%≤ |

90 |

|

|

air content%≤ |

3.0 |

|

|

Condensation time difference min (primary condensation) |

-90~120 |

|

|

Compressive strength ratio of%≥ |

1d |

140 |

|

3d |

130 |

|

|

7d |

125 |

|

|

28d |

120 |

|

|

The 28d contraction rate ratio of% |

135 |

|

Methods And Precautions

1. Recommended mixture: powder 0.5~1.5%.Liquid 2~3% " Calculated by gel material, this mixing amount is the recommended mixing amount, and its exact proportion should be determined according to the actual situation.Findetermined after coordination ratio test.

2. The powder of this product can be directly added to the mixture or used after dissolution. The liquid should deduct the water content in the solution.Post postincorporation method is better.

3. The temperature of cement should not exceed 60℃.This product is suitable for concrete construction with a daily minimum temperature of over 5℃.

4. The concrete added to this product shall appropriately extend the mixing time for 30 to 60s.

5. The product shall be stored in a cool and dry place.Prevent damp and damage.shelf life of one year.

Technical Service

1. According to the engineering situation, our company can provide relevant technical services to the concrete engineering.

2. According to the needs of the partner, our company can provide technical services such as concrete mix ratio design, construction process optimization (speeding up the construction period and cost saving), construction process control, concrete maintenance and treatment and other related technical services.