Products

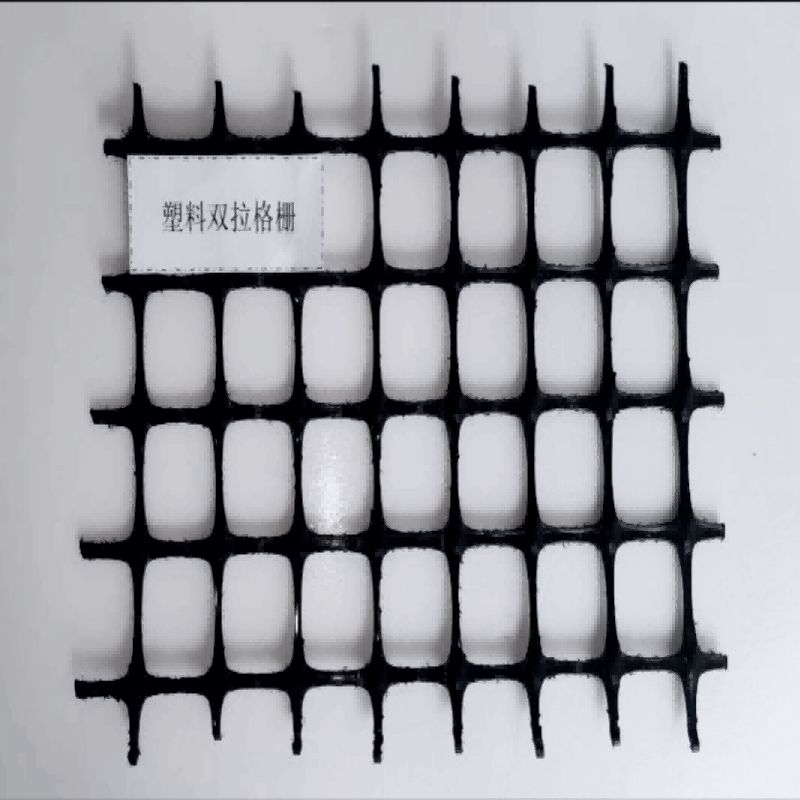

Steel-plastic Composite Geogrid

Product Characteristics

Large strength, small creep, adapt to all kinds of environmental soil, can fully meet the use of high retaining wall in high-grade roads.It can effectively improve the block locking, occlusal effect of the reinforced bearing surface, greatly enhance the bearing capacity of the foundation, effectively restrain the lateral displacement of the soil body, and enhance the stable performance of the foundation.Compared with the traditional grille, it has the characteristics of large strength, strong bearing capacity, corrosion resistance, aging prevention, large friction coefficient, uniform aperture, convenient construction and long service life.

It is more suitable for deep-sea operation and embankment reinforcement, which fundamentally solves the technical problems such as low strength, poor corrosion resistance and short service life caused by long-term seawater erosion of other materials.It can effectively avoid the construction damage caused by crushing and damage by machines and tools in the construction process.

Product Function

The tensile force of the steel and plastic compound qualified grille is borne by the high strength steel wire woven by warp and longitude, which produces a very high tensile modulus under the low strain capacity, and the vertical and horizontal ribs cooperate, giving full play to the locking role of the grille on the soil.

The steel wire latitude and longitude of the steel and plastic compound ribs are woven into a mesh, the outer inner layer is formed once, the steel wire and the outer inner layer can coordinate, and the damage elongation rate is very low (not more than 3%).The main force unit of steel-plastic composite geogrid is steel wire, with extremely low creep capacity.

Qualification

|

model |

Limit tensile strength KN / m per delay m |

Break fracture elongation% |

Extreme tensile strength was KN / m per delay meter after 100 freeze / thaw cycles |

The elongation of breaks per delay meter was% after 100 freeze-thaw cycles |

The net distance of the grid is mm |

Anti-freezing index ℃ |

Adding and welding point ultimate stripping force |

|||||

|

release |

horizontal |

release |

horizontal |

release |

horizontal |

release |

horizontal |

release |

horizontal |

|

|

|

|

GSZ30-30 |

30 |

30 |

≤3 |

≤3 |

30 |

30 |

≤3 |

≤3 |

232 |

232 |

-35 |

≥100 |

|

GSZ4O-40 |

40 |

40 |

≤3 |

≤3 |

40 |

40 |

≤3 |

≤3 |

149 |

149 |

-35 |

≥100 |

|

GSZ50-50(A) |

50 |

50 |

≤3 |

≤3 |

50 |

50 |

≤3 |

≤3 |

220 |

220 |

-35 |

≥100 |

|

GSZ50-50(B) |

50 |

50 |

≤3 |

≤3 |

50 |

50 |

≤3 |

≤3 |

125 |

125 |

-35 |

≥100 |

|

GSZ60-60(A) |

60 |

60 |

≤3 |

≤3 |

60 |

60 |

≤3 |

≤3 |

170 |

170 |

-35 |

≥100 |

|

GSZ60-60(B) |

60 |

60 |

≤3 |

≤3 |

60 |

60 |

≤3 |

≤3 |

107 |

107 |

-35 |

≥100 |

|

GSZ70-70 |

70 |

70 |

≤3 |

≤3 |

70 |

70 |

≤3 |

≤3 |

137 |

137 |

-35 |

≥100 |

|

GSZ80-80 |

80 |

80 |

≤3 |

≤3 |

80 |

80 |

≤3 |

≤3 |

113 |

113 |

-35 |

≥100 |

|

GSZ100-100 |

100 |

100 |

≤3 |

≤3 |

100 |

100 |

≤3 |

≤3 |

95 |

95 |

-35 |

≥100 |

Product Use

It can be used for civil works, such as road, railway, embankment, abutment, construction sidewalk, wharf, bank revetment, levee, dam, beach treatment, freight yard, slag yard, airport, sports field, environmental protection building, soft land base reinforcement, retaining wall, slope protection and road crack resistance, etc.