Products

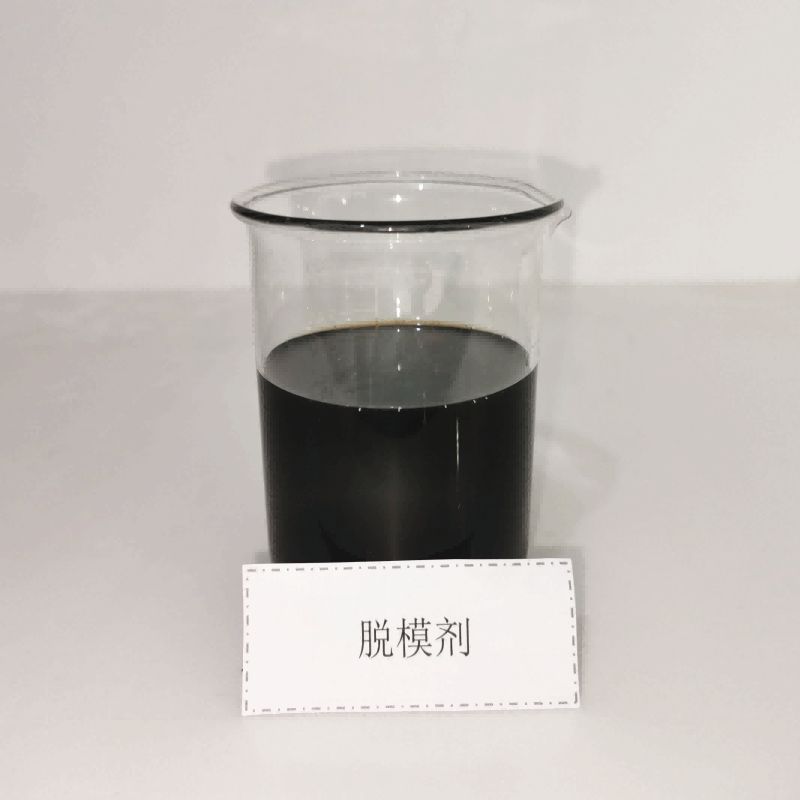

China Manufacturer for Form Release Oil - Oil demolding agent – Xiangye

China Manufacturer for Form Release Oil - Oil demolding agent – Xiangye Detail:

Usage Method

Dilution method: transfer the water to the desired concentration, and please stir well. The is diluted with clean water and sprayed on the surface of the mold. The specific dilution ratio of should be selected according to the difficulty of release molding of silicone products. Even the amount of release agent sprayed in the process of use will not cause bad appearance phenomena such as whitening, crack, watermark, oil and other surface of the product after forming oil release agent use method is simple, brush up directly, pouring concrete can be

Common problems encountered during the use of the mold release agent

1. Ineven injection- – - – - – - – - – - – - – - -improved coating

2. Spray flow- – - – - – -adjust the spraying amount

3. Wipe- – - – - – - – - – - – -select release agent hardness and solvent system

4. Evaporation- – - – - – - – - – - – - – -solid separation solubility or solvent solubility is different, orange peel phenomenon, evaporation when the solid precipitation can not form a uniform skin film, adjust the dispersant and solvent

5. Product shrinkage- – - – -shrinkage stress exceeds tension resistance, concentric marks, mainly choose material shrinkage, injection pressure and other adjustments

6. Bubble- – - – - – - – - – - -the product surface has many small bubble pits, raw material problems or release agent foaming performance, the gap between the release agent and mold into the air or the mold surface is rough, improve the hardness of release agent

7. Heat capacity of mold material- – - -mold reinforcing material heat capacity distribution is different, different heat storage, high temperature reaction is fast, or high temperature dissolution of mold release agent caused

Product detail pictures:

Related Product Guide:

Responsible excellent and fantastic credit rating standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, buyer supreme" for China Manufacturer for Form Release Oil - Oil demolding agent – Xiangye , The product will supply to all over the world, such as: Slovakia, Serbia, Seychelles, With the principle of win-win, we hope to help you make more profits in the market. An opportunity is not to be caught, but to be created. Any trading companies or distributors from any countries are welcomed.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.